Level Measurement in Closed Tanks with DP Transmitter

Learn how to accurately measure liquid levels in pressurized tanks using differential pressure (DP) transmitters for reliable readings.

InstruNexus

2.6K views • Oct 10, 2025

About this video

💧 Understanding Level Measurement in Closed Tanks

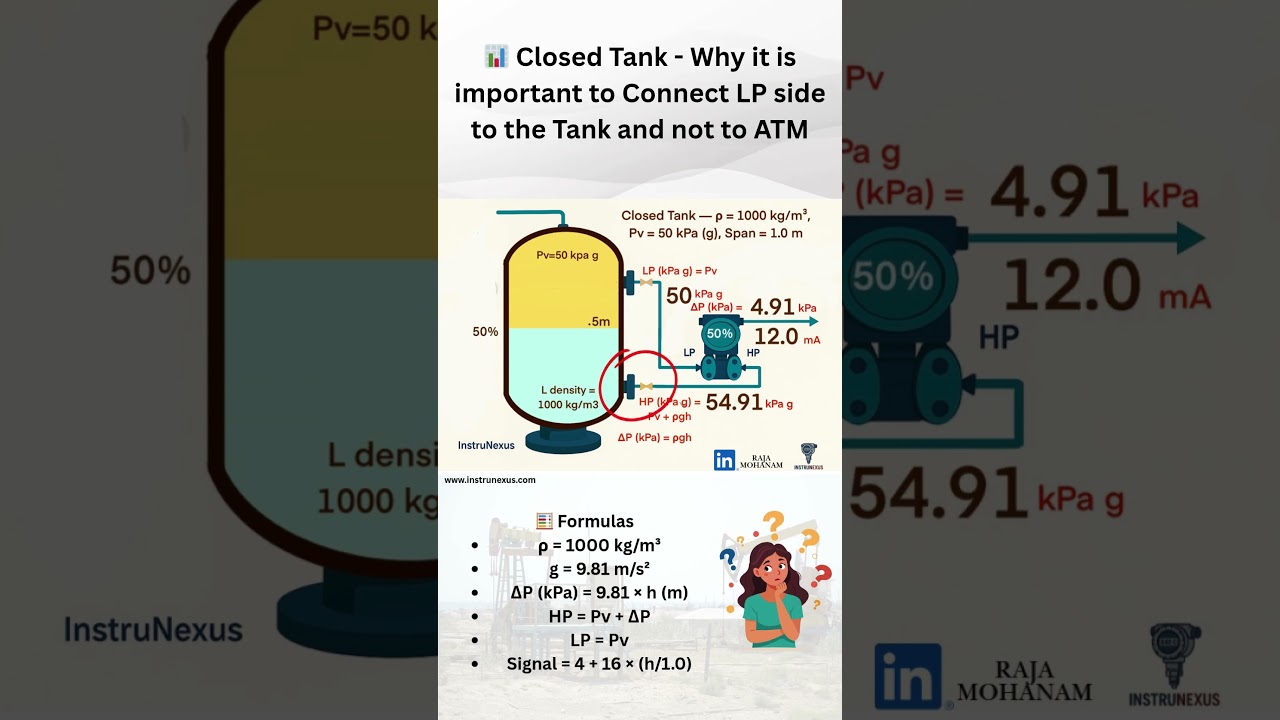

When you’re measuring liquid level in a closed or pressurized tank, it’s not just about the height of the liquid — the vapor pressure above it plays a crucial role.

Here’s the key:

In a differential pressure (DP) transmitter, the Low Pressure (LP) side is connected to the vapor space. This setup ensures that any vapor pressure in the tank is automatically compensated — so the transmitter only “feels” the true liquid head (ρgh).

✅ If the LP side is vented, changes in vapor pressure will directly affect the transmitter’s reading — leading to major level errors.

✅ If the LP side is connected properly, the vapor pressure cancels out, and the transmitter accurately measures only the liquid column.

🎯 In short:

“A properly connected LP line is the difference between an accurate level reading and a costly process error.”

This is a simple yet powerful concept every instrumentation engineer should master — especially during DP transmitter calibration and closed tank design.

Watsapp Channel : https://whatsapp.com/channel/0029VbBC5YC5kg70IIBfsS0N

Telegram : https://t.me/+HxsxzPaLkOczMTRl

You tube : https://www.youtube.com/@InstruNexus

Instagram : https://www.instagram.com/instrunexus/

Website : www.instrunexus.com

#Instrumentation #ProcessControl #LevelMeasurement #DPTransmitter #EngineeringSimplified #Instrunexus #Automation #oilandgas

When you’re measuring liquid level in a closed or pressurized tank, it’s not just about the height of the liquid — the vapor pressure above it plays a crucial role.

Here’s the key:

In a differential pressure (DP) transmitter, the Low Pressure (LP) side is connected to the vapor space. This setup ensures that any vapor pressure in the tank is automatically compensated — so the transmitter only “feels” the true liquid head (ρgh).

✅ If the LP side is vented, changes in vapor pressure will directly affect the transmitter’s reading — leading to major level errors.

✅ If the LP side is connected properly, the vapor pressure cancels out, and the transmitter accurately measures only the liquid column.

🎯 In short:

“A properly connected LP line is the difference between an accurate level reading and a costly process error.”

This is a simple yet powerful concept every instrumentation engineer should master — especially during DP transmitter calibration and closed tank design.

Watsapp Channel : https://whatsapp.com/channel/0029VbBC5YC5kg70IIBfsS0N

Telegram : https://t.me/+HxsxzPaLkOczMTRl

You tube : https://www.youtube.com/@InstruNexus

Instagram : https://www.instagram.com/instrunexus/

Website : www.instrunexus.com

#Instrumentation #ProcessControl #LevelMeasurement #DPTransmitter #EngineeringSimplified #Instrunexus #Automation #oilandgas

Video Information

Views

2.6K

Likes

29

Duration

1:01

Published

Oct 10, 2025

User Reviews

4.3

(2) Related Trending Topics

LIVE TRENDSRelated trending topics. Click any trend to explore more videos.