The Importance of Addressing EMI During PCB Design and Testing

Understanding why electromagnetic interference (EMI) should be considered early in the PCB design process rather than postponed until compliance testing, to ensure effective electromagnetic compatibility (EMC) and prevent costly redesigns.

Dario Fresu

3.0K views • Apr 23, 2025

About this video

Why You Can’t Ignore EMI Until the Testing Phase

Some engineers delay electromagnetic interference (EMI) considerations until compliance testing, assuming issues can be resolved with quick fixes.

This approach often leads to costly redesigns and project delays.

EMI is best addressed early in the design phase through:

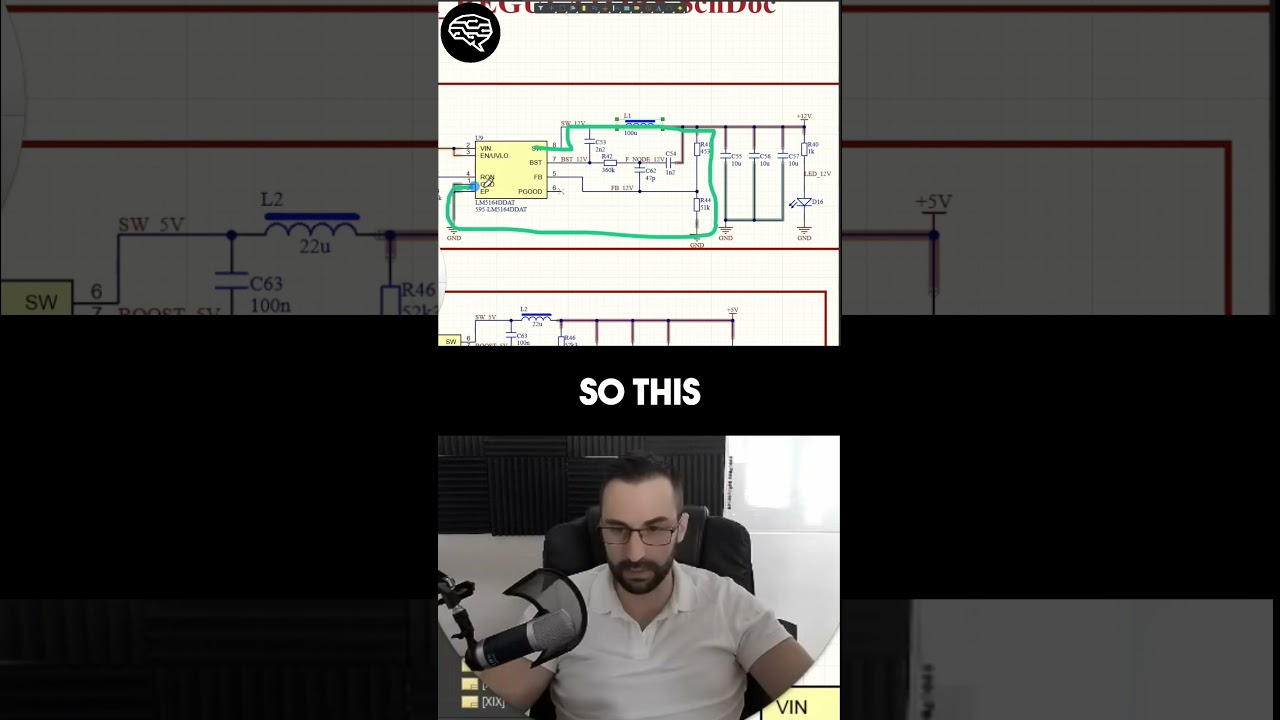

- Optimized PCB Layout: Minimize the area enclosed by current loops to reduce antenna-like structures that radiate or conduct high-energy harmonic content.

- Strategic Component Selection and Placement: Choose components and arrange them to limit EMI risks.

- Thoughtful System Architecture: Design with EMI compliance in mind from the start.

Implementing these strategies during the design phase is far more cost-effective than relying on expensive shielding or other last-minute solutions during testing.

Early intervention also provides more options for achieving compliance without compromising performance.

The key to success is understanding EMI fundamentals.

By tackling EMI proactively, you can save time, reduce costs, and ensure a smoother path to compliance.

-Dario

P.S. Want to master Electronic design and EMI/EMC control intuitively?

Check out my courses and EMI control guides at https://fresuelectronics.com

#electronics #pcbdesign #PCB #EMC #EMI

Some engineers delay electromagnetic interference (EMI) considerations until compliance testing, assuming issues can be resolved with quick fixes.

This approach often leads to costly redesigns and project delays.

EMI is best addressed early in the design phase through:

- Optimized PCB Layout: Minimize the area enclosed by current loops to reduce antenna-like structures that radiate or conduct high-energy harmonic content.

- Strategic Component Selection and Placement: Choose components and arrange them to limit EMI risks.

- Thoughtful System Architecture: Design with EMI compliance in mind from the start.

Implementing these strategies during the design phase is far more cost-effective than relying on expensive shielding or other last-minute solutions during testing.

Early intervention also provides more options for achieving compliance without compromising performance.

The key to success is understanding EMI fundamentals.

By tackling EMI proactively, you can save time, reduce costs, and ensure a smoother path to compliance.

-Dario

P.S. Want to master Electronic design and EMI/EMC control intuitively?

Check out my courses and EMI control guides at https://fresuelectronics.com

#electronics #pcbdesign #PCB #EMC #EMI

Tags and Topics

Browse our collection to discover more content in these categories.

Video Information

Views

3.0K

Likes

77

Duration

0:51

Published

Apr 23, 2025

User Reviews

4.5

(2) Related Trending Topics

LIVE TRENDSRelated trending topics. Click any trend to explore more videos.