Master Assembly Line Balancing: Cycle Time & Workstation Optimization 🚀

Learn how to calculate Cycle Time, determine the minimum number of workstations, and effectively balance an assembly line with five tasks in this step-by-step guide.

The Business Doctor

33.1K views • Jun 15, 2021

About this video

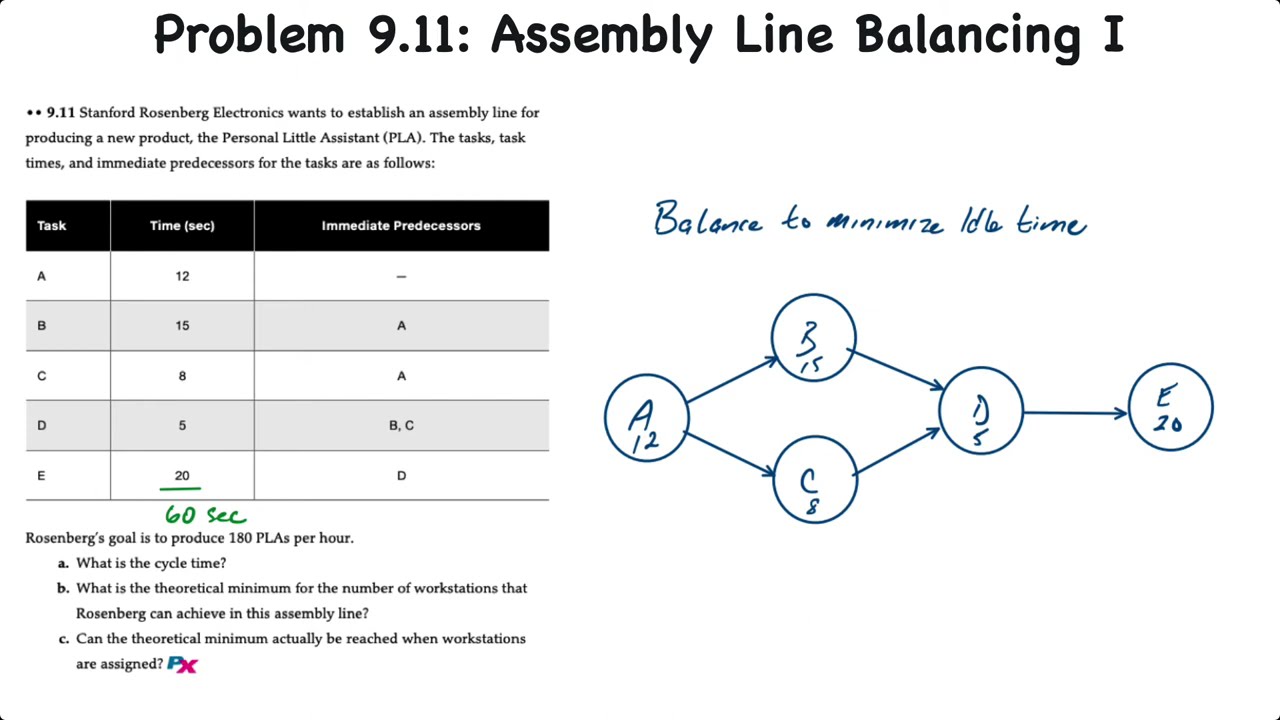

This video demonstrates how to determine the Cycle Time, Minimum Number of Workstations, and balance an assembly line with five tasks.

CORRETION:

At 1:15 the formula used to calculate cycle time shows as per day when, for this question, the production basis is hourly, so the formula should reflect that and the total number of seconds available in a single hour are 3,600 and the desired output is 180 units per hour. If there were 8 hours in a day available, the total time available would be 28,800 seconds and the output would be 1,440. The cycle time would then be 28,800 sec per day / 1,440 units per day = 20 sec/unit.

CORRETION:

At 1:15 the formula used to calculate cycle time shows as per day when, for this question, the production basis is hourly, so the formula should reflect that and the total number of seconds available in a single hour are 3,600 and the desired output is 180 units per hour. If there were 8 hours in a day available, the total time available would be 28,800 seconds and the output would be 1,440. The cycle time would then be 28,800 sec per day / 1,440 units per day = 20 sec/unit.

Tags and Topics

Browse our collection to discover more content in these categories.

Video Information

Views

33.1K

Likes

297

Duration

4:03

Published

Jun 15, 2021

User Reviews

4.3

(6) Related Trending Topics

LIVE TRENDSRelated trending topics. Click any trend to explore more videos.

Trending Now